Industries

DUNPAI’s mining screens are widely applicable for grading and filtering materials in industries like mining, road construction, stone, chemical and metallurgy.

We can provide mining screens with different designs to help you boost productivity.- In asphalt plants, our self-cleaning screens with different patterns, like diamond pattern and triangular pattern, can effectively avoid clogging problems at the bottom;

- In dry mortar industry, our combined self-cleaning wire screens, with side-tensioned hooks, can increase the efficiency of filtering, and prevent material leakage;

- In coal preparation plants, our stainless steel slotted screens can deliver excellent performance. This is because they are made of quality stainless steel, anti-abrasion materials and with advanced welding techniques;

- In the food industry, our food-grade stainless steel wire screens and screen panels are able to meet your demands for screening different food;

- In tunneling industry, our polyurethane slotted screens, featuring anti-abrasion performance, can effectively separate water from mud generated during the working of tunnel boring machine;

- In waste processing industry, our zigzag wire screens are able to filter large amounts of waste. We can substantially extend the service life of our screens and strengthen filtering efficiency by increasing the screens’ diameter without affecting the Opening Area;

- We also produce non-magnetic wire screens and screen panels that feature high-strength and abrasion-resistant performance. They are made of non-magnetic materials in a demagnetization environment. Thanks to these features, our screen products are especially suitable for production environments having high requirements for non-magnetic materials;

-

Mineral Processing

Mining screens are required to filter materials during mining and beneficiation. Unwanted materials will be filtered out in tailings.

-

Asphalt Mixing

Mining screens are required to be tough enough and have excellent resistance to abrasion, high temperature and impact.

-

Sand & Gravel

Mining screens are very important to improve the gradation of natural or artificial construction aggregate.

-

Metal & Steel

Ceramic screen mesh: equipped with patented steel-based ceramic wires; reasonable structure; resistance to impact and abrasion; long service life.

-

Construction Waste

To process and filter construction waste at scale, zigzag anti-clogging wire screens are recommended. The screens have large Opening Areas, so they can filter materials efficiently.

-

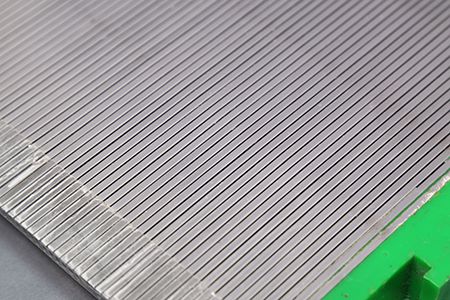

Coal

Mining screens are required to filter unwanted dust and gravel when grading raw coal. DUNPAI’s slotted wire screens are able to complete the task well.

-

Crushing & Recycling

After being crushed or broken, stones, concrete, asphalt, cinder and slag are recycled as fill products for the construction of roads and river embankments.

Founded in 1973, DUNPAI is a mining screen manufacturer based in Shanghai, China. With 50 years of constant development, the company has grown from a small factory for manufacturing mineral processing screens into a mainstay in the domestic screening surface industry. The pursuit of the highest level and excellence of our mining and aggregate screen products is our constant insistence. As early as 1985, DUNPAI has been among the frontline suppliers of wear-resistant metal screening products for the industries of steel and highway construction. Today, our range of screening surfaces includes industrial woven wire meshes, welded wire meshes, wedge wire screens, ceramic screens, polyurethane screens, rubber screens, and modular screen panels to serve a diverse range of markets including high speed railway, metallurgy, mining, chemical, food, stone, road construction, tunnel, and other industries in need of sizing, sorting, classifying, dewatering and filtration applications. The reliable performance of our screening products is highly praised by our global customers due to they can be an ideal alternative to those mining screens from world's leading brands. All our screening surfaces for screening machines are certified in accordance with ISO14315 standard, and these mining sieves have been exported to a number of countries such as Spain, Russia, India, Kenya, UK, etc. Besides, we as a mining screen supplier have partnered with Terex, Metso, Sandvik, D&G Technology, Marini, Nikko, Ammann, Tieto, Southern Road Machinery, XCMG and other renowned companies, providing them with our premium quality industrial screening products. Approved by these international companies, DUNPAI is a reliable wear-resistant screening surface manufacturer and supplier recognized by the market.

Don’t see what you are looking for or have questions? A knowledgeable representative can help.

Our Products

-

Polyurethane Screen

Tunneling industry;

To be specific: separating water from sands, muds, stones, peddles and ores. -

Modular Screen Panel

DUNPAI’s modular screen panels, metal and non-metal types, can be used and changed efficiently and conveniently.

-

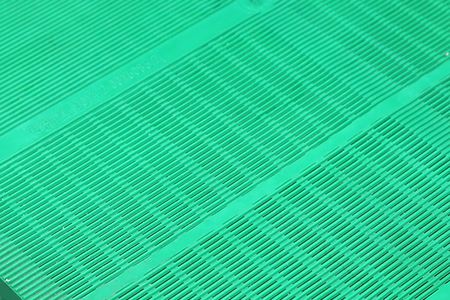

Diamond Pattern Screen

DUNPAI manufactures its diamond pattern screens with mesh shape similar to square.

-

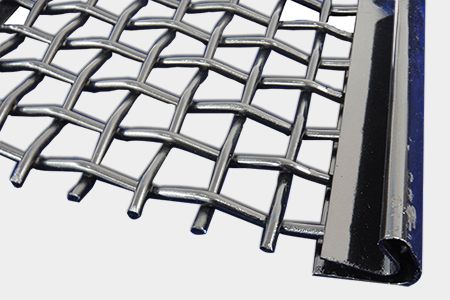

Woven Wire Mesh

Metal woven wire mesh is the most commonly used screen in the industry and features high accuracy of meshes.

Customization

We have a group of excellent R&D experts and a whole bunch of advanced manufacturing and testing devices, by which we are able to produce quality products to meet your demands.