Production

We have nearly 50 years of experiences in wire screen production. We have developed a unique production mode, in which wire screens made of polyurethane, rubber and metal are produced independently in different areas, with technologies shared among these areas.

We have thirteen production lines for woven wire mesh and eight for anti-clogging wire screens. Every step of production, from the storage of raw materials to the delivery of finished products, is under tight scrutiny. Production lines can be expanded with increasing demands.

Steel wires come from famous Belgian companies. The wires undergo heat treating and feature better abrasion resistance than normal wires. Tensile strength is customized based on the specific types of wire, allowing customers from different industries to purchase the most suitable wire screens.

Before being stored, raw materials will be tested from multiple perspectives, such as surface integrity and hardness.

Side tensioning shall be carried out after the production wire screens. Every tensioning machine can conduct its own style of side-tensioned hooks. Only the tensioning is finished compliant to technical and tolerance requirements can the wire screens be passed to the next step of production.

Rust protection coating made of environmental-friendly materials will be applied to wire screens.

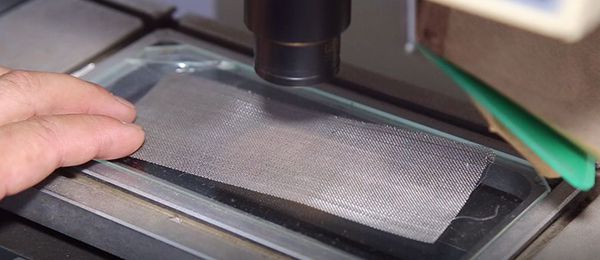

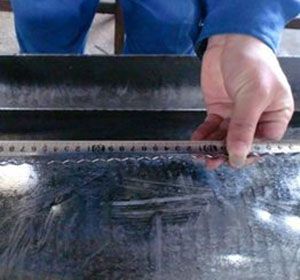

With every production step completed, each wire screen will be measured by inspectors and then be sent to warehouse for delivery.

Our factory for the production of polyurethane wire screens covers 5,000 square meters. In the factory, there are various kinds of manufacturing equipment, like injection molding machines and casting machines, enabling us to provide a one-stop service of manufacturing polyurethane wire screens at scale.

Our factory for the production of rubber wire screens covers 10,000 square meters and has different types of vulcanizing machines.

Quality Control

Tensile Strength Test

-

Symmetry Test

-

Metallographic Analysis

-

Impact Test

-

Depth Test

-

Pitch Test

-

Aperture Test for Screens with Thick Wires

-

Aperture Test for Screens with Thin Wires

Tension Test

-

Modular Screen Panel

DUNPAI’s modular screen panels, metal and non-metal types, can be used and changed efficiently and conveniently.

-

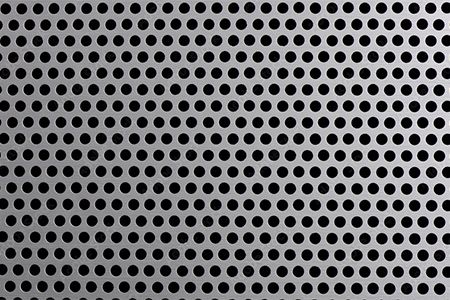

Perforated Plate Screen

Perforated plates are made by expanded mesh machines through pulling or drilling.

-

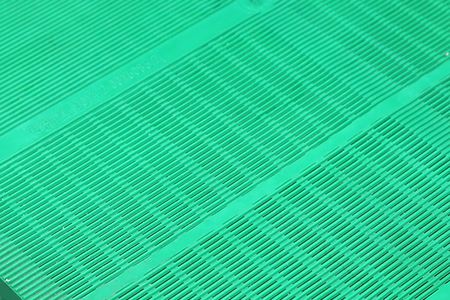

Polyurethane Screen

Tunneling industry;

To be specific: separating water from sands, muds, stones, peddles and ores. -

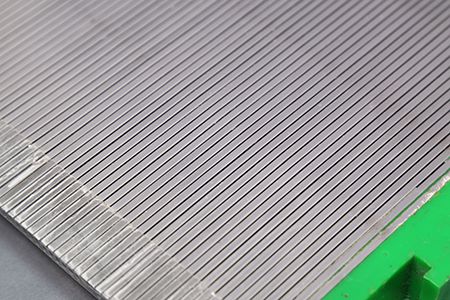

Rubber Screen

Our rubber screens are resistant to abrasion and can process hard materials, such as ores, granite, crushed stones, gravel and coal.

Customization

We have a group of excellent R&D experts and a whole bunch of advanced manufacturing and testing devices, by which we are able to produce quality products to meet your demands.