DUNPAI was founded in 1973 as a state-owned company formerly known as Shanghai Qianshao Mining Screening Factory. In 1985, we made the first foray into iron and steel industry. Later, our screens for mining equipment and asphalt plants replaced those from developed countries. In 1998, we were restructured into a joint-venture enterprise. We have been providing services for numerous domestic and international industry leaders, like Baosteel Group, Maanshan Iron & Steel, Terex and Sandvik. Today, we own one sales company, three manufacturing companies and a total of 20 automatic and semi-automatic wire screen production lines.

Product Videos

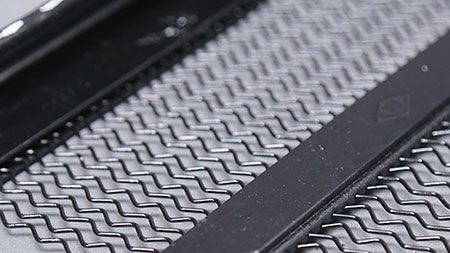

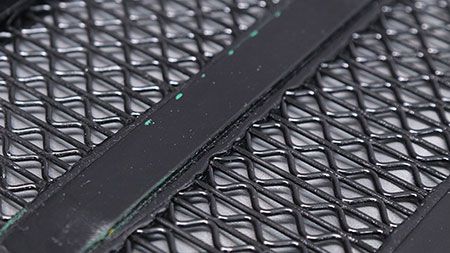

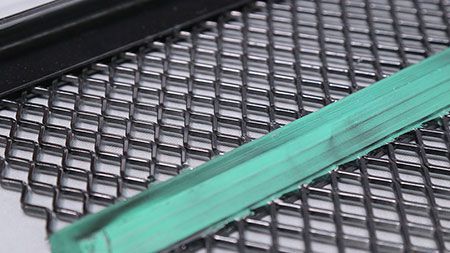

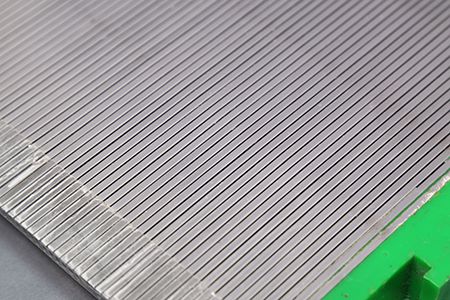

Our mining screens are made of different high quality materials, for instance, high-manganese steel, stainless steel, polyurethane and rubber. In particular, high-manganese steel and stainless steel are turned out from China’s quality raw materials and subjected to heat treatment process for hardening. After that, the materials are pulled into different shapes, such as circles, trapezoids and triangles through world's leading forming processes, the tensile strength and hardness of these materials are certified with ISO14315 international standard. This means our mining screens are hard and resilient enough to be used for quite a long time.

-

Modular Screen Panel

DUNPAI’s modular screen panels, metal and non-metal types, can be used and changed efficiently and conveniently.

-

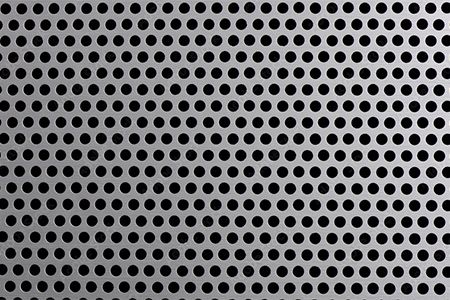

Perforated Plate Screen

Perforated plates are made by expanded mesh machines through pulling or drilling.

-

Polyurethane Screen

Tunneling industry;

To be specific: separating water from sands, muds, stones, peddles and ores. -

Rubber Screen

Our rubber screens are resistant to abrasion and can process hard materials, such as ores, granite, crushed stones, gravel and coal.

Customization

We have a group of excellent R&D experts and a whole bunch of advanced manufacturing and testing devices, by which we are able to produce quality products to meet your demands.